This structured approach to commissioning is important for creating a cleanroom atmosphere that not just meets Preliminary style and design and operational requirements but additionally maintains its overall performance after some time.

The organization experienced only recently commenced a cleaning validation plan at enough time with the inspection and it absolutely was regarded as insufficient by FDA. Amongst the reasons it was viewed as inadequate was the organization was only on the lookout for proof of your absence with the former compound. The business had proof, from TLC tests within the rinse h2o, of the presence of residues of response byproducts and degradants through the preceding method.

The V design in commissioning and qualification is actually a framework that assures a technique’s performance is tested towards its primary design and style technical specs. It provides a structured approach to validating which the technological Remedy shipped meets the supposed results.

Verify to determine that a immediate measurement of your residue or contaminant has long been produced for that rinse water when it can be utilized to validate the cleaning process.

Throughout the exploration of cleanroom qualification and its critical steps, we’ve underscored the significance of stringent specifications and meticulous organizing in guaranteeing the efficacy and compliance of cleanrooms across highly regulated industries.

Gases and vapors have distinctive Bodily and chemical Qualities such as smell, coloration, ignition temperature, explosion pressures and many others. Supplied the amount of gases and vapors encountered in field it is not functional to recognize gases separately for that functions of hazardous area classification.

Intrinsically Protected methods are usually Employed in instrumentation and more info control purposes. Intrinsically Safe and sound devices usually do not release electrical or thermal Electricity to bring about ignition. Intrinsically Protected units typically use Zenner boundaries or Galvanic isolation.

These enclosures may have thinner walls as compared with enclosures rated for Course I installation. The development of such enclosures is referred to as dust-ignition proof. Confer with Short article 100 on the NEC for definitions of Dust-Ignition proof products.

Choice media to People detailed can be utilized delivered that they're validated for the reason supposed.

Safe storage or processing demands an idea of the feasible hazards linked to sensitivity to versions in temperature

Environmental Checking: Threat assessment tools assist in analyzing best spots and frequencies for environmental checking. Things such as room temperature, humidity, presence of drains, and room occupancy are regarded as to ensure extensive contamination clean room validation Command.

The most crucial objective of hazardous area classification structure would be to facilitate the choice of correct machines and set up techniques to make certain the devices can run securely in that atmosphere and doesn't cause fires or explosions.

The dangerous area classification method establishes essential protection procedures and approaches for electrical installations in The situation.

Dangerous area classification will help us detect these pitfalls so we can easily select appropriately rated tools to be certain a secure and reliable operating facility.

Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Romeo Miller Then & Now!

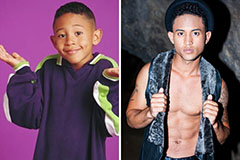

Romeo Miller Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!